Understanding Flanges: Types and Applications

The Basics of Flanges

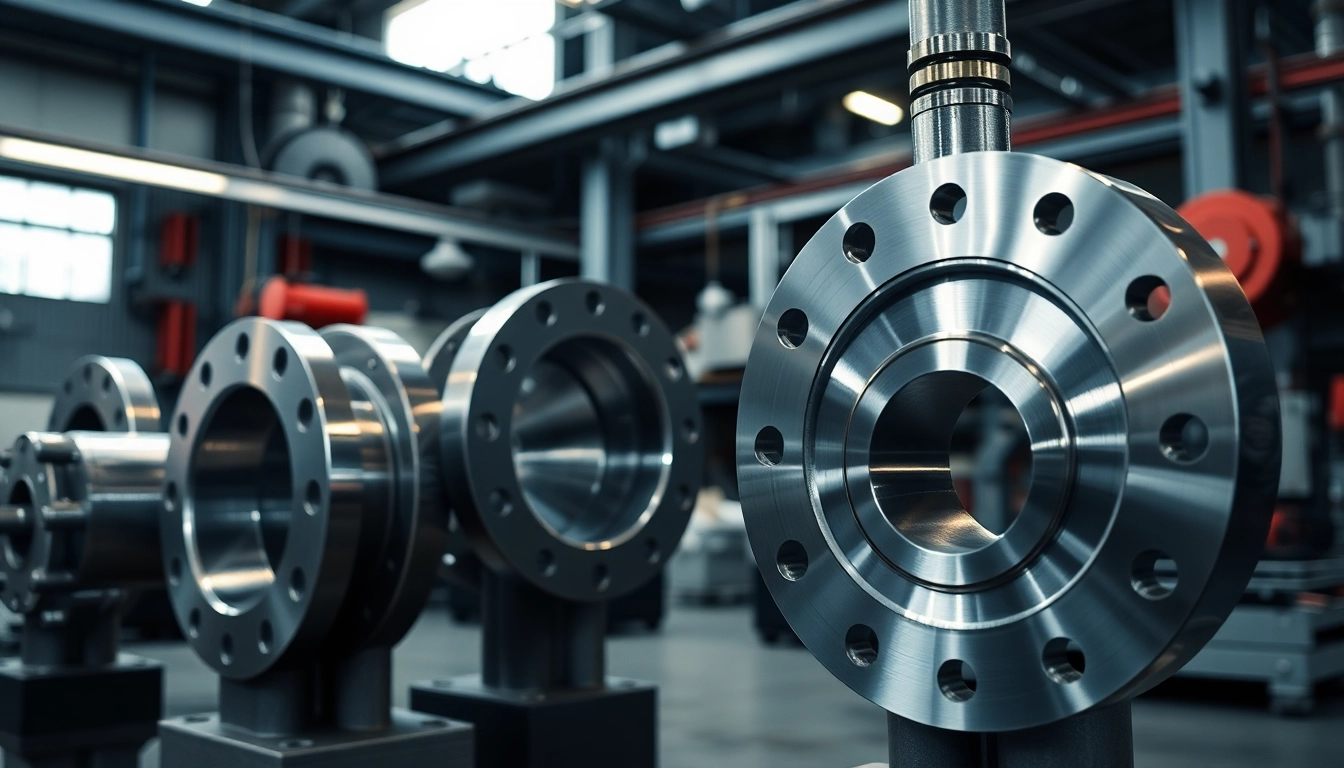

Flanges are integral components in piping systems that serve as mechanical connectors. They create a robust link between two segments of piping or between a pipe and a vessel. Flanges facilitate easy assembly and disassembly, which is vital for maintenance and inspection tasks. With a variety of designs and materials, flanges can cater to different pressures, temperatures, and fluid types, ensuring optimal performance in various applications. For those seeking quality flanges, understanding the intricacies of these components is essential for effective project management.

Common Types of Flanges and Their Uses

Flanges come in several types, including:

- Weld Neck Flanges: These flanges are designed for high-pressure applications and are characterized by a long neck, which allows for a stronger weld. They are commonly used in pipelines and pressure vessels.

- Slip-On Flanges: Easy to install, slip-on flanges are placed over the pipe and welded in place. They are often used in low-pressure applications.

- Blind Flanges: These flanges are solid and do not have a hole, serving as a cover for the end of a pipe. They are used when a pipeline needs to be sealed off.

- Socket Weld Flanges: These are similar to slip-on flanges but are designed to be inserted into the flange for increased strength. They are used in high-pressure applications.

- Threaded Flanges: These flanges have internal threads and are screwed onto the pipe, suitable for low-pressure applications where welding is not feasible.

- Lap Joint Flanges: These flanges are used in conjunction with a stub end and are perfect for applications requiring frequent dismantling.

Selecting the Right Flanges for Your Project

Choosing the correct flange involves careful consideration of multiple factors, such as the type of fluid being transported, pressure, temperature, and compatibility with existing materials. Other considerations may include:

- Pressure Ratings: Ensure the flange can handle the maximum pressure of your application.

- Size Compatibility: Select flanges that match the size of your piping system to avoid leaks.

- Material of Construction: Choose materials that can withstand the service conditions and are resistant to corrosion.

Materials and Manufacturing Processes for Flanges

Popular Materials Used in Flange Production

Flanges can be manufactured from a wide variety of materials, each suited for specific applications. The most common materials include:

- Carbon Steel: Widely used due to its strength and durability. It’s suitable for standard applications but must be coated or alloyed for corrosion resistance.

- Stainless Steel: Renowned for its excellent corrosion resistance and strength, making it ideal for a variety of industries, including food processing and pharmaceuticals.

- Alloy Steel: Often used in high-pressure and temperature applications, such as oil and gas exploration.

- Plastic Flanges: Used in applications where corrosion resistance is paramount and in chemical manufacturing.

- Ductile Iron: Known for its toughness, it is often used in municipal and industrial water applications.

Manufacturing Techniques: Casting, Forging, and Machining

Flanges can be fabricated using several manufacturing processes, including:

- Casting: This method involves pouring molten metal into a mold. It allows for complicated shapes but may have dimensional tolerances.

- Forging: This technique involves shaping the metal using compressive forces, yielding a stronger product. Forged flanges are suitable for high-stress applications.

- Machining: Flanges can also be machined from solid blocks of metal. This process allows for very precise dimensions and high-quality finishes.

Quality Standards in Flange Manufacturing

Quality assurance is vital in flange manufacturing. Various organizations establish standards to ensure performance, including:

- ASME: The American Society of Mechanical Engineers sets guidelines for pressure vessel and piping components.

- API: The American Petroleum Institute includes specifications for flanges used in the oil and gas industry.

- ISO: International Organization for Standardization provides global construction and testing standards.

Installation Best Practices for Flanges

Preparation Steps Before Installation

Proper installation is crucial for maximizing the performance of flanges. Preparation should include:

- Cleaning the surfaces of the pipes and flanges to ensure a proper seal.

- Inspecting the flange gasket and ensuring it is compatible with the fluids being handled.

- Confirming that the flanges are of the proper type for the application and are aligned correctly.

Common Installation Mistakes to Avoid

Small mistakes can lead to significant problems during flange installation. Common issues include:

- Improper torqueing of bolts, leading to uneven pressure, which can result in leaks.

- Neglecting to use a gasket or using the wrong type, compromising the seal.

- Ignoring alignment issues between flanges, which can cause excessive strain on the system.

Tools and Equipment Required for Proper Installation

To install flanges correctly, ensure access to the following tools and equipment:

- Torque Wrench: For applying the correct torque to the bolts.

- Gasket Material: Essential for creating a seal between flanges.

- Flange Alignment Tools: To verify that the flanges are aligned properly before tightening.

- Cleaning Supplies: To prepare the surfaces for installation.

Maintenance and Inspection of Flanges

Routine Maintenance Guidelines for Longevity

Regular maintenance of flanges is essential to ensure their longevity and functionality. Recommendations include:

- Conducting regular visual inspections for signs of wear or corrosion.

- Monitoring the tightness of bolts and conducting periodic torque checks.

- Replacing gaskets as needed, especially if leaks are detected.

Signs of Wear and When to Replace Flanges

Identifying when to replace flanges is critical to maintaining system integrity. Signs of wear include:

- Visible rust or pitting on the surface.

- Frequent leaks around the flange joint.

- Deformation of the flange or gasket material.

Safety Inspections: Ensuring Operational Integrity

Safety inspections should be an integral part of any maintenance routine. Key points to check include:

- Evaluating the condition of all sealing surfaces.

- Checking for signs of thermal expansion issues in high-temperature applications.

- Assessing for any fluid leaks that could indicate failure.

Trends in Flange Design and Industry Innovations

Recent Innovations in Flange Technology

The flange industry continues to evolve with innovations, such as:

- Advanced sealing technologies that improve leak prevention.

- Smart flanges integrated with sensors for real-time performance monitoring.

- Modular flange designs that allow for easier maintenance and modifications.

Eco-Friendly Materials and Sustainable Practices

With an increasing focus on sustainability, the flange industry is adopting eco-friendly materials and practices such as:

- Utilizing recycled metals in flange production.

- Implementing energy-efficient manufacturing processes.

- Developing biodegradable gaskets for specific applications.

Future Directions in Flange Applications

The future of flanges will likely see their use expanding into new industries and applications, including:

- Increased use in renewable energy systems, like wind and solar.

- Development of specialized flanges for extreme environments, such as space exploration.

- Integration with IoT technologies for enhanced monitoring and performance analytics.