What is Cross Sectioning?

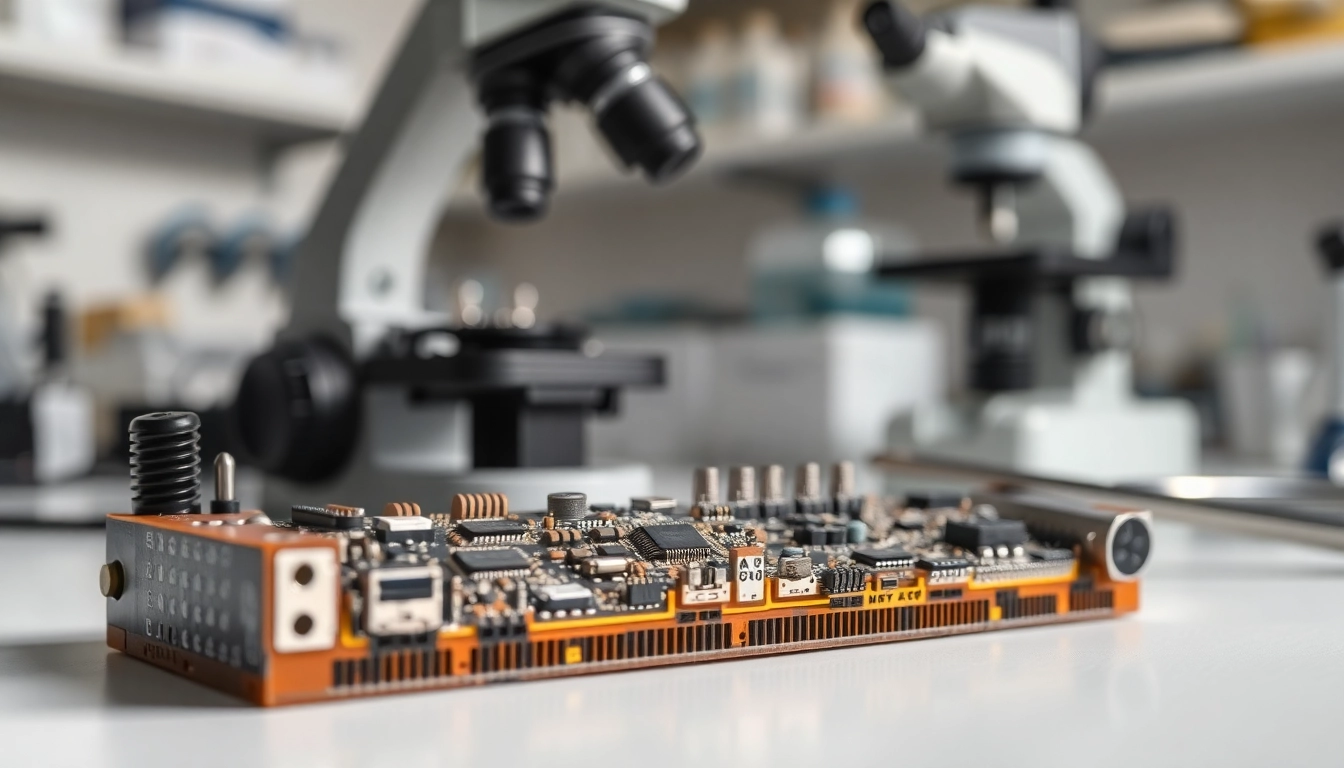

Cross sectioning, often referred to as microsectioning, is a crucial technique in the fields of electronics and materials science that involves creating a slice of an object to reveal its internal structures. This methodology allows researchers and engineers to understand the intricacies of components, materials, and assemblies, often hidden from surface inspection. By preparing a sample that cuts through the object at a specific plane, analysis becomes possible in ways that are fundamental to development, quality assurance, and failure analysis.

This process is pivotal not only for research and scientific exploration but also for industrial applications where the integrity of materials and components is essential. A well-executed cross sectioning provides a wealth of information, enabling deeper insights into the design and functionality of electronic devices and materials alike. For more detailed insight into this transformative technique, explore cross sectioning.

Definition and Historical Background

The term “cross section” is derived from geometry, describing a technique of slicing an object to gain a representation of its internal features. Historically, this method has been utilized across various scientific fields, evolving from basic manual techniques to sophisticated methods incorporating advanced technology.

The roots of cross sectioning in electronics can be traced back to early materials analysis in laboratories. Over the years, as electrical components became more complex, the need for deeper internal investigation increased, leading to the adoption of specialized cutting and analysis equipment. Today, this technique is recognized not only for its utility but also as an indispensable part of modern engineering and reliability testing.

Applications in Electronics and Engineering

Cross sectioning finds widespread applications in numerous industries, particularly in electronics, where understanding the physical layout of a circuit board or semiconductor die is essential. In the electronics industry, cross sectioning is often used to inspect the quality of manufacturing processes, validate material compositions, and identify potential failure modes.

In engineering, cross sectioning is utilized in fields such as materials science and structural analysis. It aids in the evaluation of composites, the examination of welds, and the assessment of failure analysis in mechanical systems. By enabling a detailed examination of internal layers, cross sectioning can uncover defects, layer separations, and other critical issues that could affect product performance and reliability.

Cross Sectioning Techniques Overview

The process of cross sectioning is not homogeneous; it incorporates various techniques tailored to specific materials and objectives. The primary methods can be categorized into mechanical and chemical techniques, each offering unique benefits and considerations. Understanding these techniques is essential for selecting the right approach for a given application.

Common Methods in Cross Sectioning

Mechanical vs. Chemical Methods

Mechanical cross sectioning typically involves the use of saws, grinders, or lapping machines to create thin slices of materials. This method is widely appreciated for its ability to produce high-quality sections without altering material properties. However, it may not be suitable for all materials, especially brittle ones that can fracture during the cutting process.

On the other hand, chemical methods utilize etching solutions to dissolve material and reveal internal structures. This approach is advantageous for achieving micro-level detail but can introduce its own set of challenges, such as controlling etching rates and ensuring uniformity across sections. Understanding these methods allows implementers to weigh trade-offs in precision, speed, and material integrity.

Best Practices for Sample Preparation

Successful cross sectioning begins with proper sample preparation. The objective is to obtain a slice that accurately represents the internal structure while minimizing damage. Some best practices include:

- Selecting appropriate cutting tools based on the material type.

- Using coolant or lubricant during mechanical cutting to reduce heat generation and prevent alterations to the material structure.

- Employing careful mounting techniques to securely hold samples in place during cutting.

- Conducting preliminary examinations using non-destructive methods, such as X-ray imaging, to determine the optimal cutting plane.

By adhering to these practices, technicians can improve the quality of their cross sections and the reliability of subsequent analyses.

Tools and Equipment Used

The arsenal of tools available for cross sectioning is diverse, catering to various materials and techniques. Commonly employed tools include:

- Precision saws, such as diamond saws, for cutting hard materials.

- Grinding and polishing machines that enhance section flatness and surface finish.

- Etching stations equipped with chemical baths for producing microscopic cross sections.

- Microscopes and imaging systems for detailed analysis of cross-sectioned samples.

Choosing the correct combination of equipment is vital in achieving optimal results, as each tool serves specific purposes within the cross sectioning process.

Benefits of Cross Sectioning in Analysis

Enhanced Visibility of Internal Structures

One of the most significant advantages of cross sectioning is its ability to reveal internal structures that are otherwise invisible. This enhanced visibility allows for precise assessments of material compositions and configurations.

For example, in circuit boards, cross sectioning can uncover hidden vias, layer separations, and solder joints. These insights are critical for identifying defects or manufacturing inconsistencies that may affect the performance or reliability of electronic devices.

Cost-Effectiveness in Quality Control

Incorporating cross sectioning into quality control procedures can lead to significant cost savings. By identifying defects early in the manufacturing process, companies can minimize the risk of product failure in the field. This proactive approach streamlines the development process and reduces expensive recall situations.

Adding cross sectioning to routine inspections also enhances the overall quality of products, leading to increased customer satisfaction and loyalty. The cost of implementing such measures can be quickly offset by the savings garnered from reduced failure rates and improved product performance.

Time-Saving Advantages in Testing

Time efficiency is another major benefit of cross sectioning. Traditional testing methods often require multiple roundabout processes to ascertain material integrity. Cross sectioning allows for quick assessments, thus speeding up the testing phase significantly.

The ability to perform both qualitative and quantitative analysis within a single cross section further streamlines testing protocols, providing immediate feedback that can directly influence design and manufacturing processes. Adopting cross sectioning in testing workflows ultimately accelerates the pathway to market.

Challenges and Considerations

Potential Risks in Sample Preparation

Despite its advantages, cross sectioning also presents challenges. One major risk lies in the sample preparation phase. Improper handling or cutting can lead to defects that obscure the desired internal features.

Addressing these risks requires stringent adherence to preparation protocols and might involve additional preliminary checks, such as using non-destructive evaluation techniques to assess sample integrity before cutting. It is crucial to implement a robust quality control process to mitigate these risks effectively.

Limitations of Various Cross Sectioning Methods

Different cross sectioning methods come with their own limitations that can affect the outcome of the analysis. For instance, mechanical techniques may introduce micro-fractures in brittle materials, while chemical etching might not completely reveal certain internal features due to selective dissolution.

Understanding these limitations is key for practitioners. They should prioritize selecting the best method according to sample characteristics and the analysis goals, thus enhancing the reliability of the resulting data.

Best Practices to Mitigate Issues

To optimize the cross sectioning process and reduce potential issues, implement the following best practices:

- Conduct a thorough initial assessment using non-destructive techniques.

- Utilize controlled environments during sample preparation to limit contamination risks.

- Train technicians extensively on the equipment and methodologies to minimize human errors.

- Document procedures meticulously to enhance reproducibility and aid in troubleshooting.

Employing these practices not only enhances the quality of the results but also contributes to a safer, more efficient working environment.

The Future of Cross Sectioning Technology

Emerging Trends in Automation

The landscape of cross sectioning technology is continually evolving, with automation emerging as a transformative trend. Automated systems are becoming increasingly sophisticated, enabling faster and more precise cross sectioning processes while significantly reducing the scope for human error.

These innovations allow for higher throughput and consistency across samples, making them particularly beneficial for high-volume manufacturing settings. As the technology matures, expect to see expanded applications across various fields, from electronics to biomedical devices.

Innovations in Precision Cutting Tools

Advancements in cutting tools are catalyzing improvements in cross sectioning methodologies. New materials and blade designs are enhancing cutting efficiency while maintaining sample integrity. Innovations such as ultra-thin diamond blades, high-speed precision saws, and automated polishing machines are all contributing to achieving superior cross sections.

These tools allow for the refinement of cross sectioning processes, enabling researchers and engineers to explore more complex materials and designs with greater ease and accuracy.

Impact of Cross Sectioning on Future Developments

As industries continue to innovate, the role of cross sectioning is poised to become even more critical. With the ongoing push for higher performance, smaller form factors, and increased reliability in electronic and material designs, cross sectioning will provide the analytical foundation necessary for success.

Looking ahead, we can anticipate further integration of cross sectioning with other analytical methods, fostering a more comprehensive understanding of how materials and designs interact under various conditions. This holistic approach will ultimately support the development of next-generation technologies geared towards higher efficiency and sustainability.