Understanding Turnkey PCB Assembly

In the rapidly evolving electronics industry, the demand for efficient, reliable, and cost-effective solutions is paramount. Turnkey PCB Assembly has emerged as a leading solution that streamlines the manufacturing process. This comprehensive guide will explore the intricacies of turnkey PCB assembly, detailing its definition, benefits, processes, challenges, and future trends.

What is Turnkey PCB Assembly?

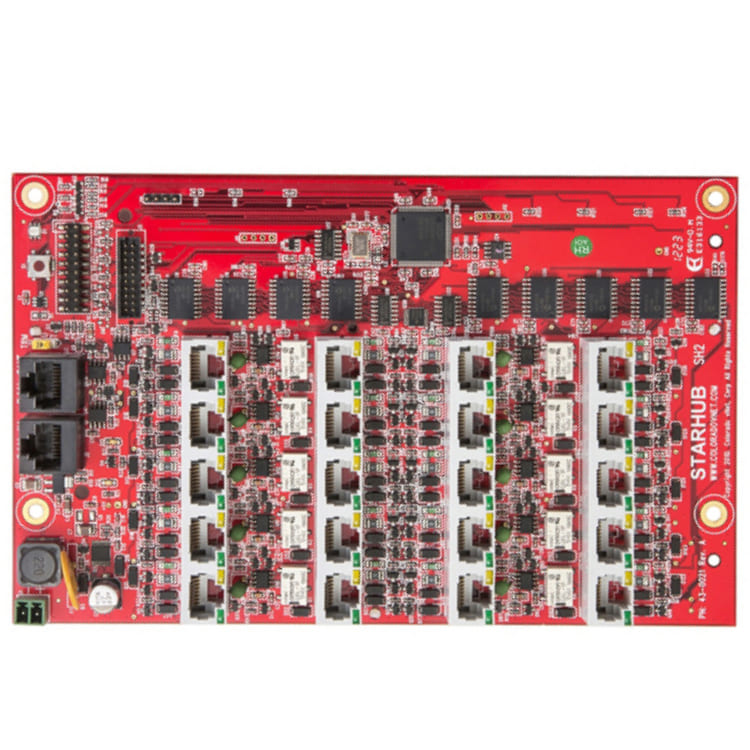

Turnkey PCB assembly refers to an end-to-end manufacturing solution where a single vendor manages the entire production process. This includes design, prototyping, manufacturing, assembly, testing, and delivery of printed circuit boards (PCBs). Clients typically provide project specifications, while the turnkey provider handles everything else—offering a seamless way to bring electronics to market efficiently.

Key Components of Turnkey PCB Assembly

The core elements involved in a turnkey PCB assembly process can be broken down into several stages:

- Design and Prototyping: Initial circuit designs are created and prototypes are built to validate functionality.

- Component Sourcing: The provider is responsible for procuring high-quality components at competitive prices.

- Assembly: This phase employs various processes such as Surface-Mount Technology (SMT) and Through-Hole technology to assemble the boards.

- Testing: Comprehensive testing ensures the functionality and quality of the assembled PCBs, using automated and manual methods.

- Logistics: The provider manages shipping and delivery to ensure timely arrival at the client’s location.

The Importance of Choosing Turnkey Solutions

Selecting a turnkey solution can significantly simplify the complexity of PCB production for many businesses. By consolidating the supply chain with a single partner, companies can minimize communication errors, enhance project visibility, and accelerate time-to-market. Additionally, a turnkey provider often has established relationships with component suppliers, which can enhance sourcing efficiency and reduce costs.

Benefits of Turnkey PCB Assembly

Speed and Efficiency in Production

The turnkey PCB assembly model is designed to optimize production timelines. By integrating design, sourcing, assembly, and testing under one roof, the lead time is drastically reduced. This means shorter cycles from prototype to production, allowing companies to respond quickly to market demands and competitive pressures.

Cost-Effectiveness of Turnkey PCB Assembly

Cost savings are a significant benefit of utilizing turnkey PCB assembly. Through bulk purchasing of components and streamlined processes, providers can offer lower prices than if individual components were sourced separately. Moreover, businesses benefit from reduced labor costs since fewer personnel are needed for project management and coordination.

Quality Assurance in Assembly Processes

High-quality standards are paramount in PCB manufacturing. Turnkey providers often implement rigorous testing protocols, ensuring that every PCB meets specified performance criteria before delivery. This consistency not only enhances product quality but also reduces the potential for defects and product recalls, which can be costly in terms of both finances and reputation.

Turnkey PCB Assembly Process Overview

Initial Design and Prototyping

The assembly process begins with the design phase. Engineers create a detailed schematic of the circuit, specifying the components and layout. Once the design is validated, a prototype is developed, providing a tangible representation to test functionality and design concepts. Rapid prototyping technologies help expedite this stage by allowing for quick modifications and iterations.

Component Sourcing Strategies

Effective component sourcing is crucial for maintaining both project timelines and cost efficiencies. Turnkey providers often maintain extensive networks of suppliers, allowing them to source components at competitive rates. Additionally, they can mitigate risks associated with supply chain disruptions by having multiple suppliers available for crucial components.

Assembly and Testing Protocols

The actual assembly of the PCB takes place using advanced machinery and skilled technicians. Each stage of assembly consists of detailed quality checks, including visual inspections and automated testing. After assembly is complete, final testing is conducted to ensure the PCB functions as intended and meets all quality standards before shipment.

Common Challenges in Turnkey PCB Assembly

Managing Supply Chain Risks

Supply chain risks are inherent in any manufacturing process, and turnkey PCB assembly is no exception. Disruptions can arise from various factors, including political unrest, natural disasters, or supplier bankruptcy. Robust risk management strategies and establishing relationships with multiple suppliers can mitigate these concerns.

Quality Control Issues in PCB Assembly

Despite comprehensive testing protocols, quality control issues can occur, sometimes leading to performance failures or defects in final products. Implementing stringent quality management systems and continuous monitoring can help address these challenges, ensuring that deviations from quality standards are swiftly dealt with.

Timing and Delivery Constraints

While turnkey solutions are geared towards efficiency, unexpected delays can still occur—whether due to unforeseen supply chain disruptions or technical difficulties. Establishing clear communication channels and setting realistic timelines allows for better management of expectations and enhances client satisfaction.

Future Trends in Turnkey PCB Assembly

Automation in PCB Assembly Processes

Automation is revolutionizing the PCB assembly industry. With advancements in robotic assembly and AI-driven inspection systems, the efficiency of the manufacturing process is set to increase further. Automation not only enhances speed but also improves precision, reducing the likelihood of human error.

The Role of AI in Turnkey Solutions

Artificial Intelligence (AI) is beginning to play a significant role in PCB assembly, particularly in areas like component placement and quality assurance. AI algorithms can analyze data from previous production runs to optimize processes, predict potential failures, and ensure quality benchmarks are met, thus driving overall efficiency.

Sustainability Trends in PCB Manufacturing

As sustainability becomes increasingly critical across various industries, PCB manufacturers are adopting eco-friendly practices. This includes reducing waste during production, utilizing recyclable materials, and implementing energy-efficient processes. Transitioning to greener practices not only helps the environment but can also position companies favorably in the market as consumers become more environmentally conscious.